Risk analyses

Risk analysis is one of the most important steps in ensuring product or machine safety. Its purpose is to systematically evaluate which hazards may arise during use installation maintenance or other stages of the product life cycle. A well-executed risk analysis helps prevent hazardous situations before they occur and creates a strong foundation for a safe compliant product.

At Revismo we do not treat risk analysis as paperwork. We approach it as a practical engineering tool that improves product safety, supports product development and ensures the solution meets both user expectations and regulatory requirements.

Why is risk analysis necessary?

Risk analysis is a mandatory part of proving CE conformity and without it a product cannot be placed on the European market correctly. A CE risk analysis shows that the manufacturer has identified potential hazards, understands the associated risks and has implemented suitable measures to reduce or eliminate them.

Beyond legal requirements risk analysis is also necessary for practical reasons. It helps identify weaknesses in the structure control logic or usage logic and makes it possible to apply improvements early when changes are simpler, faster and more cost-effective. This reduces the chance that problems appear only during operation or in the worst case during an incident.

What hazards does risk assessment help identify early?

Risk assessment highlights both obvious and hidden hazards. These may include mechanical hazards, electrical hazards, hot surfaces, unexpected start-up user errors, maintenance related risks or automation failures. Often the most dangerous hazards occur in exceptional situations or during non-standard use.

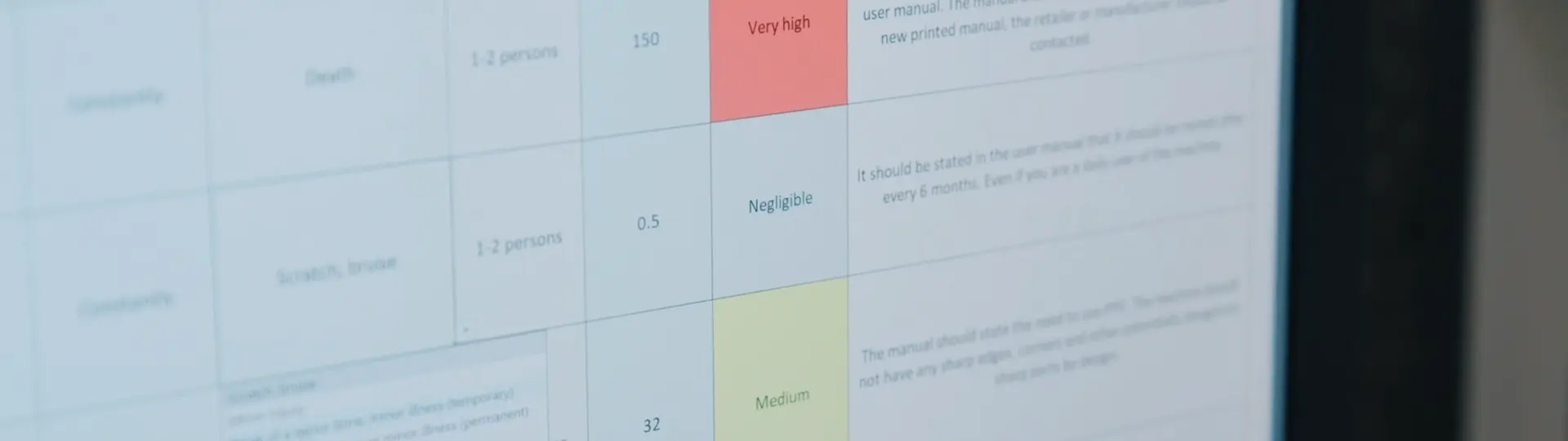

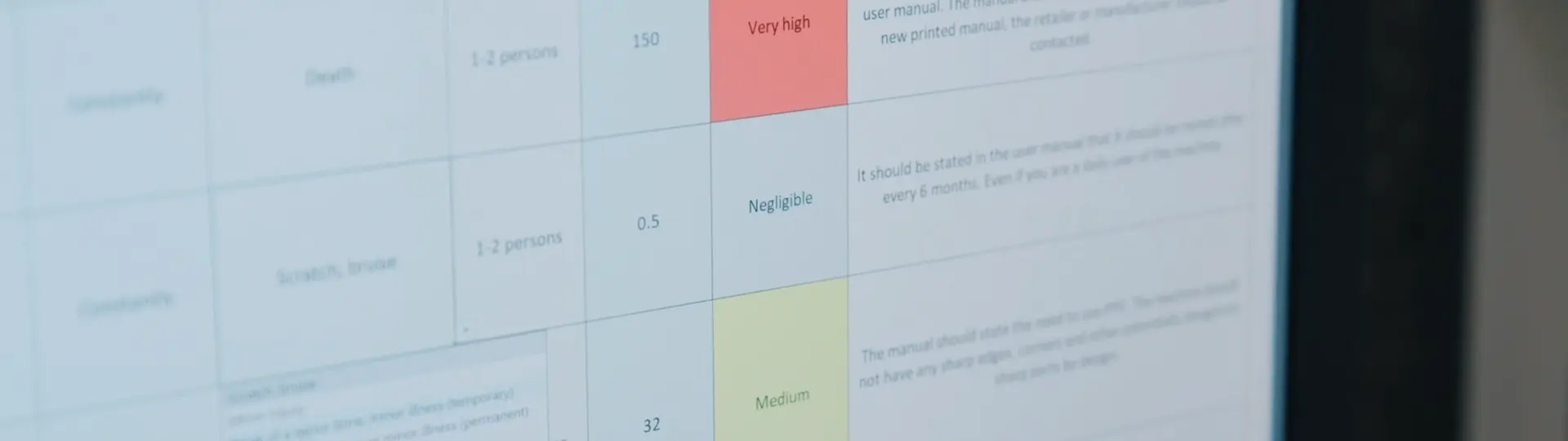

During the analysis each risk is evaluated based on likelihood and severity of consequences. This leads to a risk matrix that helps decide which risks require immediate action and which are acceptable. The result is a clear structured overview of the complete risk picture.

Which standards and directives define the content of a risk analysis?

The content and structure of a risk analysis are defined by standards and directives depending on product type and application area. A key foundation is machine safety standards including ISO 12100 which describes general principles for hazard identification and risk reduction. Other requirements may apply such as the Machinery Directive, the Low Voltage Directive and additional CE related obligations.

Revismo maps the relevant standards and regulations for each project and ensures that the device risk analysis meets current requirements in both content and format.

What does the risk analysis service look like at Revismo?

The risk analysis process begins with collecting the necessary inputs. We need technical drawings, models, descriptions of work cycles, automation logic and information about the operating environment. If some information is missing we work with you to clarify it.

We then map device functions and actions, identify potential hazard sources and connect them to specific usage scenarios. Each risk is assessed, mitigation measures are defined and their adequacy is verified. Results are delivered in a clear readable format that can be included in CE documentation and used in internal processes.

Why choose Revismo as your risk analysis partner?

Revismo’s strength lies in an engineering-driven approach and practical experience. We do not fill tables just to satisfy a requirement. We think alongside you and focus on measures that genuinely improve safety. A well-performed risk analysis helps prevent future incidents, reduces liability risks and increases user confidence and peace of mind.

Get in touch with us and let’s clarify your product safety before risks turn into problems.