Strength analyses

Strength analysis is an essential part of engineering with the purpose of evaluating how a structure component or machine withstands loads and environmental influences. It is a way to verify whether a solution is safe, reliable and compliant with applicable standards and to identify situations where there is a risk of failure, excessive deformation or other types of malfunction. A well-executed analysis helps prevent scenarios where problems only emerge during use often when the consequences are already costly, time-consuming or even dangerous.

At Revismo we view strength analysis as a tool that creates clarity. It supports better decision-making, confirms the validity of chosen solutions and highlights early on where reinforcement or rethinking is required.

Why is strength analysis essential in development?

Modern product development comes with high expectations. Products are expected to be lightweight, durable, safe and cost-efficient at the same time. This is where strength analysis becomes critical because it provides knowledge rather than intuition. Through analysis we identify stresses and deformations, evaluate how a structure behaves under different operating conditions and verify whether the solution stays within acceptable limits.

Strength analysis is often required for documentation and compliance purposes such as CE marking certification or customer approval. Just as often it also improves development itself by making structures easier to manufacture, reducing material usage or optimising weight without compromising reliability.

What safety and reliability risks does strength analysis help prevent?

The greatest value of strength analysis lies in risk prevention. When stresses or deformations become excessive the result may be cracking breakage, loosened fastenings, vibration-induced failures or unexpected fatigue failure. This is especially critical in situations where failure could endanger people or cause material damage whether involving industrial machinery metal structures or safety-critical products.

Strength analysis also helps prevent so-called silent problems. These include situations where a product does not fail immediately but gradually loses accuracy wears unevenly or begins to generate unwanted resonance. Such issues often grow unnoticed during use and eventually lead to warranty cases downtime or unexpected repairs.

What loads and effects do we analyse at Revismo?

At Revismo we perform a wide range of analyses from simple static checks to complex simulations. Depending on the nature of the product and associated risks we analyse for example:

- static loads

- dynamic effects including impacts and accelerations

- vibration and frequencies

- temperature changes and thermal stresses

- fatigue loads and the effects of repeated cycles

- buckling pressure and vacuum conditions

- snow loads and wind loads

- drop tests

In many cases the key is not only performing calculations but selecting the correct methodology and realistic usage scenarios. This is where the true value of strength analysis is created.

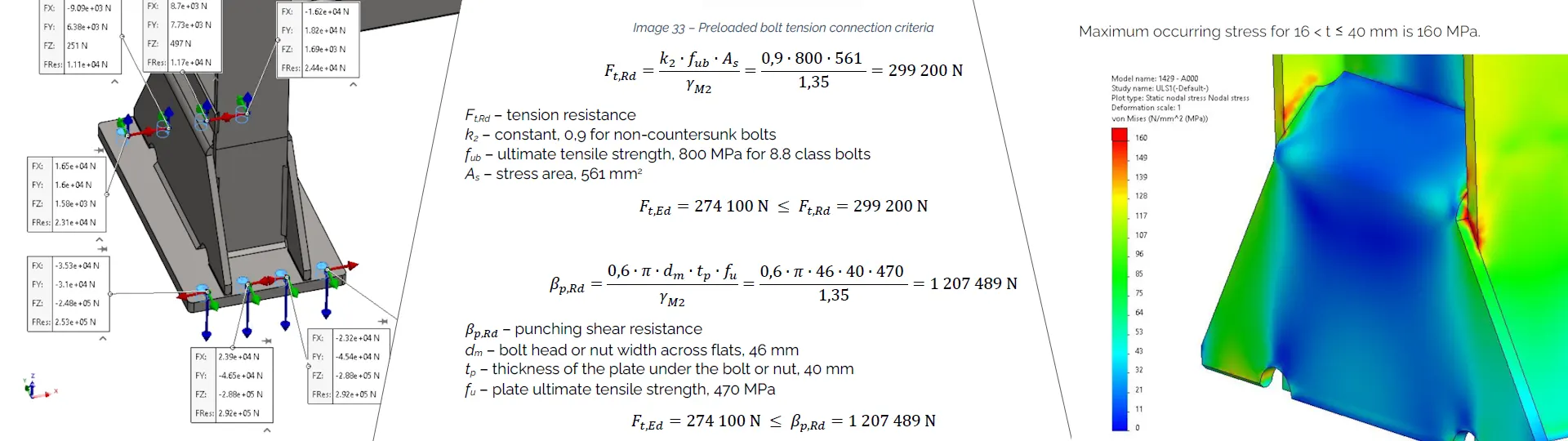

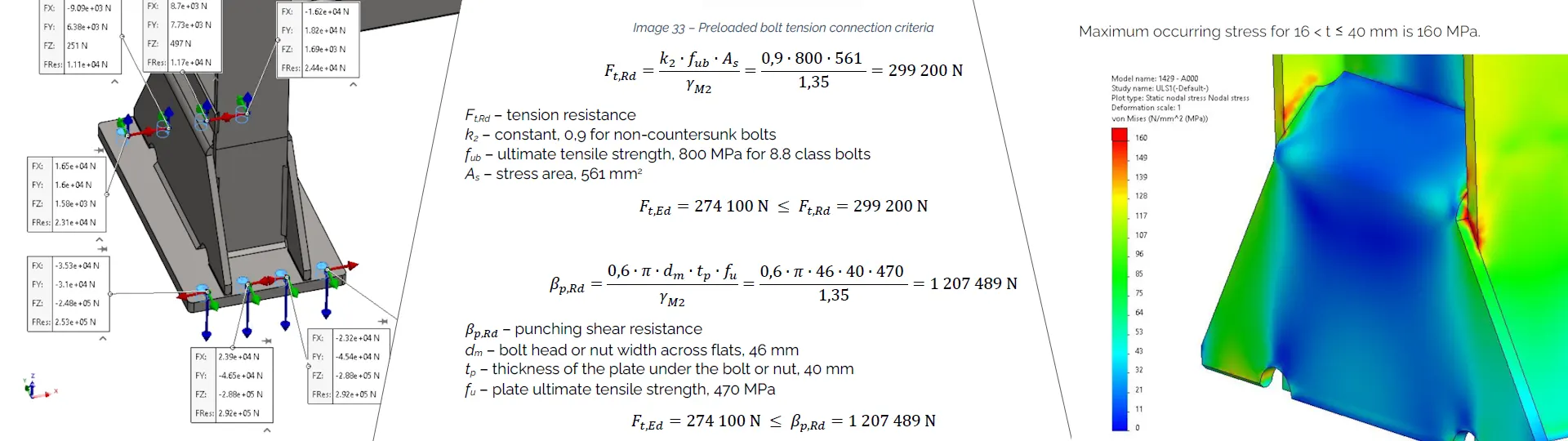

How are strength analysis results presented?

The work does not end with a plot or visual output. The result of a Revismo strength analysis is a clear and usable summary and when required a detailed technical report. The report describes input data such as the model materials loads and boundary conditions, the applied methodology and the results including stresses deformations, safety factors and critical areas.

Such documentation can be used for internal decision-making as well as for CE marking certification or customer review. When needed we also provide recommendations on how to improve or optimise the structure. This is where strength calculations become a practical development tool rather than a simple compliance check.

What types of projects does Revismo have experience with in strength analysis?

Revismo has experience across a wide range of projects and industries where structural reliability and safety are critical. We perform analyses for individual machine components as well as for larger structures including complex cases involving dynamics vibration temperature effects or fatigue.

Our strength lies in practical engineering thinking and the ability to identify critical weak points that may not be obvious at first glance.

Get in touch with us and let us verify the strength of your structure before production begins.