In Estonia, many tragic accidents related to work occur every year. Last year, 3296 accidents at work were registered, an average of 8 accidents per day. In the wake of these accidents, people often ask themselves, “Have we done all we can to prevent accidents at work?”.

At this point it is relevant to talk about the importance of risk analysis. Products and machinery manufactured and marketed in the European Union have to comply with the requirements of various standards and directives, and a very important part of the requirements for products and equipment is to carry out a proper risk assessment. The purpose of risk analysis is to identify, assess and mitigate hazards in order to reduce and prevent the risk of accidents.

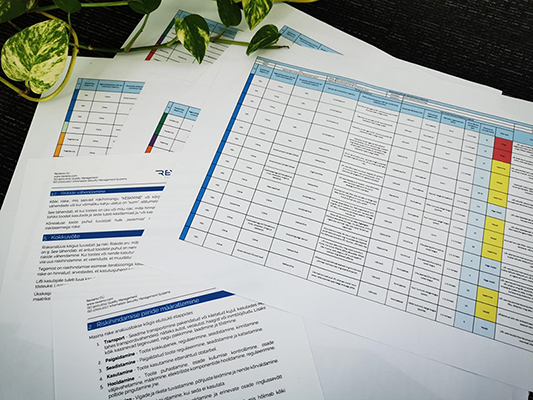

Risk analysis is one of the most important phases in the development process at Revismo. We carry out risk analyses of products, equipment and machinery, where we provide an overview of potential hazards and risks and develop measures to mitigate them. The risk analysis is also the main basis for drawing up a proper operating and maintenance manual. Revismo’s mechanical engineer Rasmus Koop is now also a holder of the prestigious CMSE® (Certified Machinery Safety Expert) certification, which covers all areas from risk analysis to safety concept development and the correct procedure for placing products and machinery on the market.

Thus, thanks to its experienced professionals, Revismo offers its clients risk analysis solutions that meet their unique needs. Whether it is a risk assessment of serial products, machinery or production lines, Revismo has the competence to carry out professional analyses in this field.

For more information on the risk analysis services offered by Revismo, please contact us.