Although Flagmore, a leading Nordic flagpole manufacturer, specializes in producing flagpoles, the company is expanding its portfolio to include light poles. Revismo played a key role in developing their new light pole product line by conducting a comprehensive strength analysis to ensure compliance with the international standard EN 40.

The project involved analyzing fiberglass composites, which are inherently complex and demanding from a strength analysis perspective. The goal was to ensure the structural integrity and stability of the poles while optimizing material usage – a critical factor for the product’s cost and competitiveness.

The Revismo team, including Mirko Arras, Ardo Tiits, and Joosep Lillemägi, utilized SolidWorks Premium’s specialized composite material analysis module, along with custom calculation templates developed by Revismo.

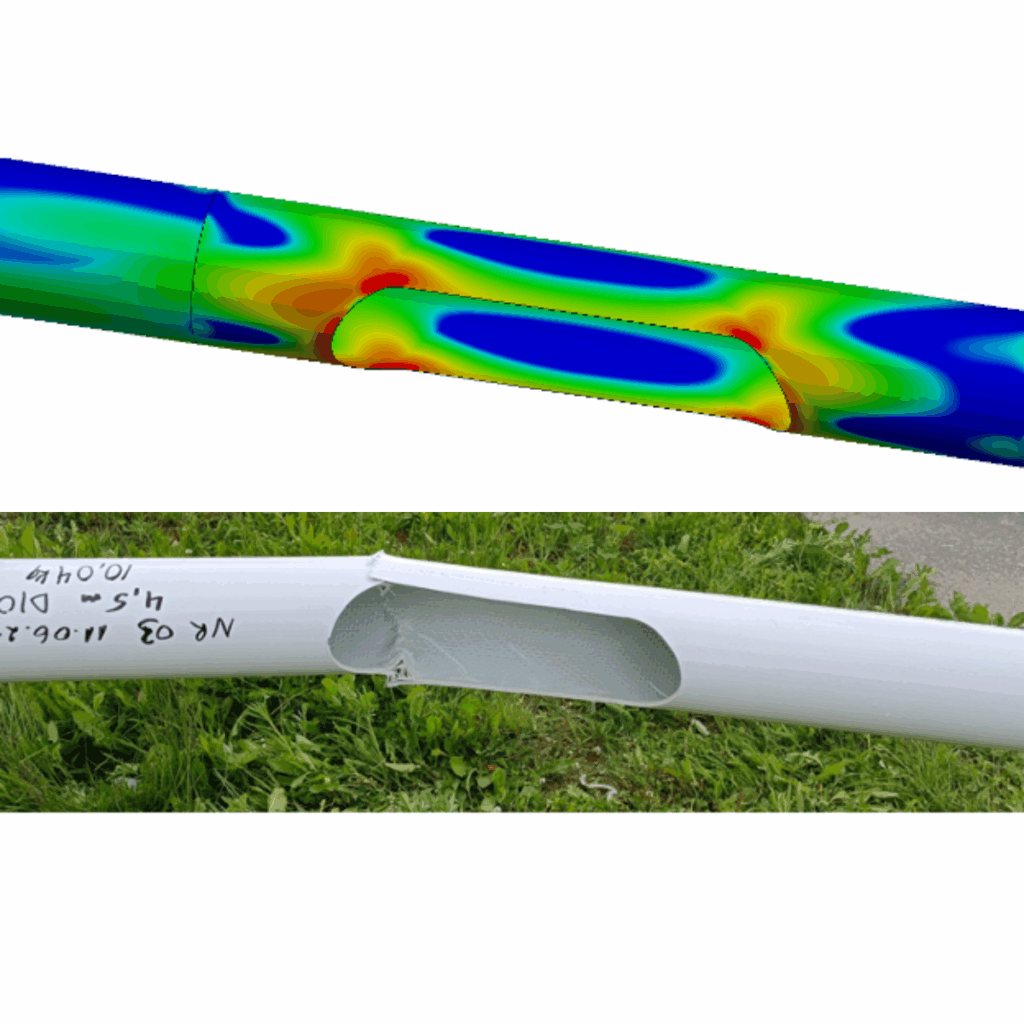

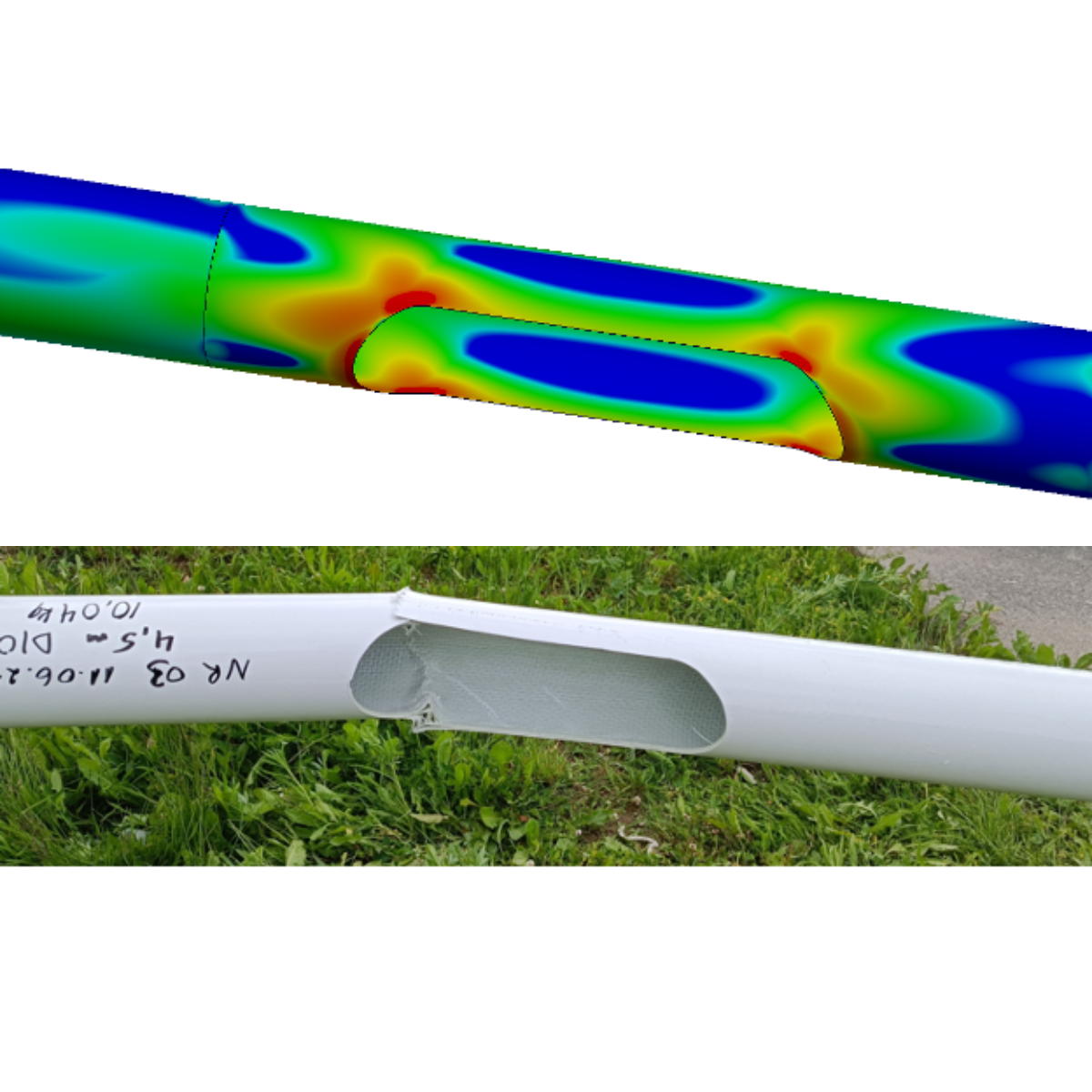

A methodology for reliable simulation of both light and flagpoles made from composite materials was established during the project. The simulations were based on material test results provided by TalTech, enabling the creation of an accurate composite material model. The calculations simulated the required breaking force, deflection at failure, and the natural frequency of the poles.

To evaluate the strength of the composite material, the well-known Tsai-Wu failure criterion was applied. Additionally, buckling calculations were performed to address failure caused by buckling, which proved to be both reliable and precise. The virtual model allowed for process optimization and cost reduction by adding material only where it was structurally necessary.

To validate the simulation results, Flagmore conducted physical destruction tests on the poles. These results were confirmed by the Swedish research institute RISE, which tested and certified the poles according to the simulations.

This collaboration highlights Revismo’s expertise in engineering analysis and innovation, providing reliable and cost-effective solutions that meet international standards.