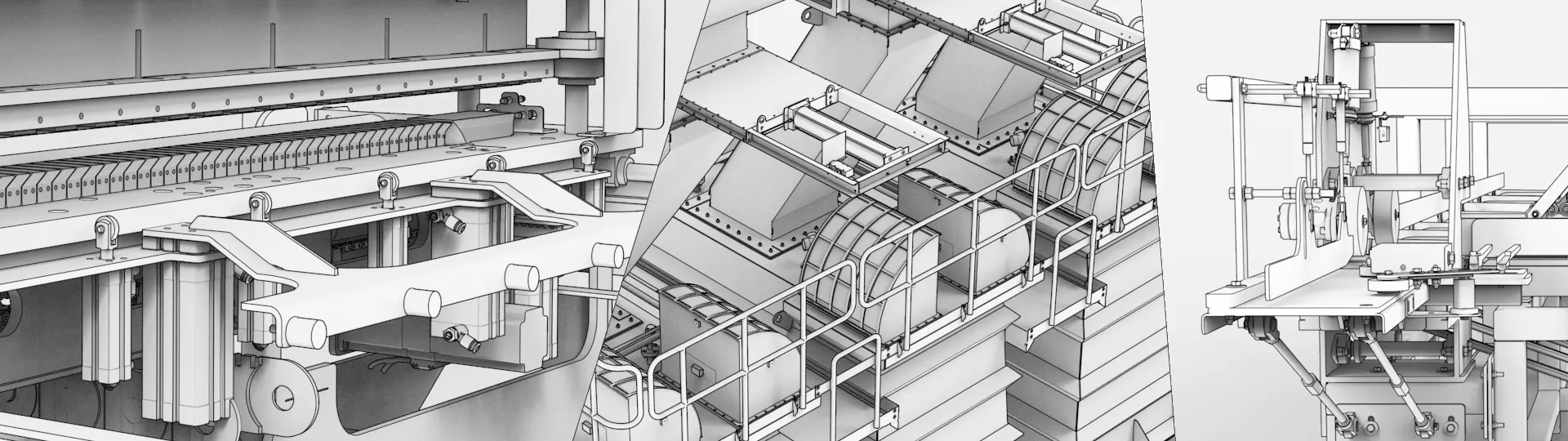

CAD Design

CAD design is the foundation of modern engineering because it allows products, structures and machines to be fully thought through before a single part is manufactured. A well-built model is not just a visual representation but a precise working tool that makes it possible to evaluate fit reliability and manufacturability at an early stage. This creates development that moves forward with confidence, saves resources and avoids costly surprises later on.

At Revismo CAD design is always part of a broader engineering service. Our goal is to create 3D models that are realistic production-ready and technically sound and to deliver documentation that is clear, unambiguous and truly usable.

What is CAD design and why is it so important in engineering?

CAD design or Computer-Aided Design means planning and engineering a product or device from a 3D model all the way to technical drawings and production-ready files. In simple terms it means building the product virtually before building it in real life. This makes it possible to see early on how parts fit together whether the solution is logical and which areas need improvement before production begins.

In engineering this early insight is critical. A 3D model helps assess strength and reliability, verifies assembly and serviceability and allows regulatory and CE considerations to be addressed before costs and risks start to escalate. When everything is carefully thought through in the virtual environment development becomes smoother, changes are easier to manage and the final result is more robust and production-ready.

How does a CAD design service accelerate development?

A well-structured CAD design service speeds up development primarily because the product can be assembled, reviewed and refined virtually before prototyping or production starts. This reduces repetition, shortens development cycles and helps keep budgets under control.

Another key advantage is flexibility. Changes can be implemented quickly in the CAD environment and carried through consistently into drawings and manufacturing files. This means development does not need to restart after every change but can move forward steadily with purpose and direction.

What problems does CAD design help prevent at an early stage?

CAD design often reveals the issues that would otherwise become expensive later on. Early in the process it becomes clear whether there is enough space between components, whether interfaces and fastenings make sense, whether the assembly sequence is truly feasible and whether maintenance access has been properly considered. The model also helps prevent situations where geometry is impractical for manufacturing or where purchased components do not integrate correctly with designed parts.

When these critical points are resolved early the need for repeated prototypes is reduced and development stays on a clear path. The result is greater confidence, fewer disrupted schedules and a calmer journey toward a finished solution.

What does the CAD design process look like at Revismo?

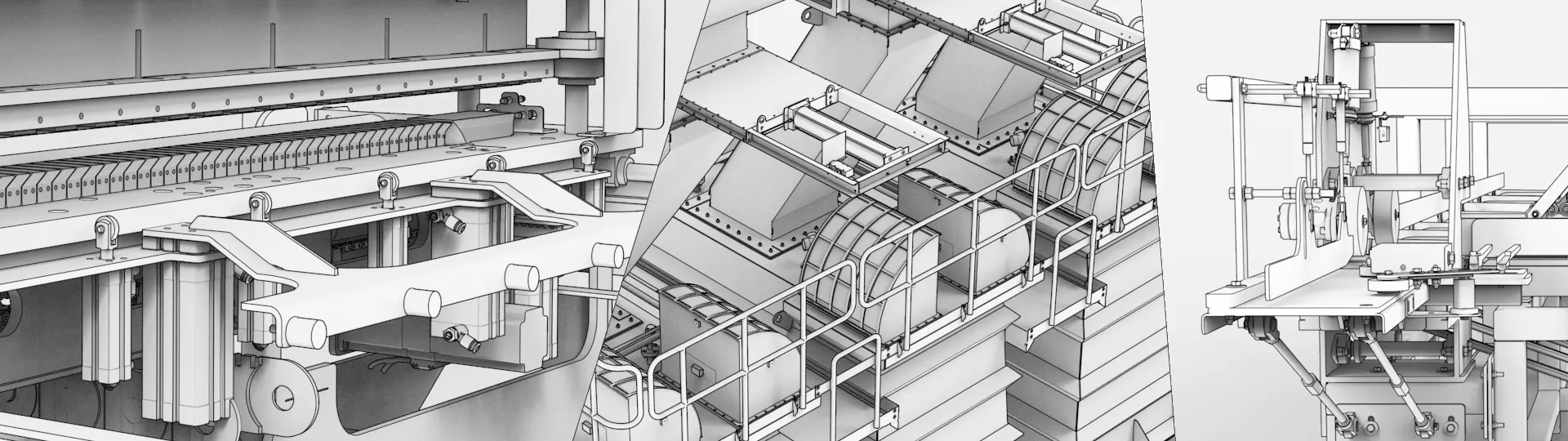

Our work always begins with understanding the need and defining the goal. We assess operating conditions constraints and when required regulatory requirements to ensure the solution starts in the right direction. We then move into the 3D modelling phase where we create the product or device model, integrate purchased components, select manufacturing methods and already consider production and assembly logic within the model.

Once the model has matured we move on to technical documentation. This is where 3D CAD drafting comes into play. We prepare technical drawings, assembly drawings and when required cutting files and CNC machining files. The goal is to give production a clear and reliable foundation and to ensure information flows through the project in a structured and consistent way rather than becoming fragmented.

What types of products does Revismo most often design with CAD?

Revismo has experience across a wide range of projects but most often we design machines and devices structural solutions automation systems and products where mechanical components must work seamlessly with electronics and software such as IoT solutions and smart devices. We also support the digitalisation of existing products through reverse engineering or by converting legacy drawings into modern CAD formats that are easier to maintain, develop and manufacture.

Why choose Revismo as your CAD design partner?

Revismo’s strength lies in a holistic perspective. We do not look at a model only through an engineer’s lens but consider production assembly use and maintenance as part of the same whole. This results in CAD design that is practical, reliable and genuinely implementable. Our focus is not on individual parts but on solutions that work as complete systems and stand up to both regulatory requirements and real-world use.

Our work progresses step by step with a clear and logical structure and pricing is transparent depending on scope either hourly-based or project-based.

Get in touch with us and give your idea form by turning it into a well-thought-out and manufacturable CAD solution.